5 axis cnc machining centre This CNC vertical machining center's highly rigid and accurate double column structure and low center of gravity in workpiece movement (trunnion table) enable both heavy-duty cutting and . I’m gathering up wooden boxes for winter projects I can do inside. I have enjoyed seeing all the magic you do with your finds. I found a long narrow case that was for music stands and brought it home (someone had thrown it away!), now that is going to be a challenge!

0 · what is 5 axis milling

1 · what does 5 axis mean

2 · small 5 axis cnc mill

3 · benefits of 5 axis machining

4 · 5 axis trunnion machining

5 · 5 axis machining explained

6 · 5 axis machining basics

7 · 5 axis cnc explained

Box steel beams offer a balance between strength and weight. The hollow section reduces the overall weight of the beam while maintaining structural integrity. This makes box beams suitable for applications where weight .

This CNC vertical machining center's highly rigid and accurate double column structure and low center of gravity in workpiece movement (trunnion table) enable both heavy-duty cutting and .

cnc machine repair service texas

Okuma's 5-axis machine tools offer 5-Axis Auto Tuning and Collision Avoidance .5-axis machining is an effective means to reduce setups and increase accuracy for multi-sided and complex parts. The shorter travels and compact footprints of the Haas UMC-500 Series .Okuma's 5-axis machine tools offer 5-Axis Auto Tuning and Collision Avoidance Software. There's a reason shops are turning to 5-axis CNC machines–they continue to produce exponential benefits and higher returns. Eliminate thermal .

what is 5 axis milling

Linear roller guides with excellent rigidity are utilized in the X-, Y-, and Z-axes to achieve powerful cutting and high-accuracy machining. The NC rotary table utilizes a roller gear cam for high-accuracy machining over extended periods .5-axis machining is easier and less expensive than you think, and can dramatically increase your profits. This versatile 5-axis universal machining center can position parts to nearly any angle .

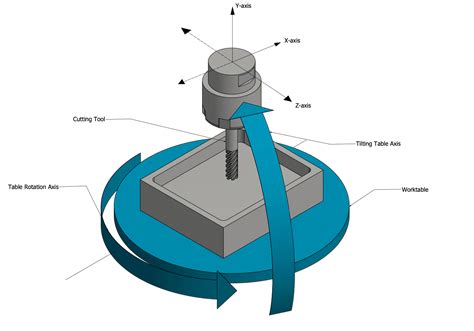

Increase speed and precision with 5-axis vertical machining. The Makino rotary axes’ speed reduces your cycle time, while our dynamic accuracies produce a higher quality surface finish.5-Axis Vertical | Machining Center The MX-520 is as efficient as it is adaptable, with customizable table and pallet options, high rigidity, and high precision. Tailored to fit numerous production needs, its automated operation and .On a 5-axis machining center, the cutting tool moves across the X, Y and Z linear axes as well as rotates on the A and B axes to approach the workpiece from any direction. In other words, you .The Northwood 5-Axis CNC Moving Table Machining Centers can feature a range of different spindle offerings of up to 40HP. For larger work envelopes – Z axes travel can accommodate .

what does 5 axis mean

small 5 axis cnc mill

With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry into 5-sided machining, the compact DMU models open the door to 5-axis .

Okuma has horizontal and vertical machining centers, including 5-axis machines, in a variety of sizes and configurations to meet any manufacturing needs.

Our MU-6300V 5-axis vertical machining center achieves high efficiency and high productivity in 5-axis, multi-sided machining. This CNC vertical machining center's highly rigid and accurate double column structure and low center of gravity in workpiece movement (trunnion table) enable both heavy-duty cutting and high-speed finishing.

The five axes of a 5-axis CNC machine are X, Y, Z (linear) and A and B (rotational). Understanding the unique function of each allows machinists to unlock the full potential and capabilities of the machine. In many machines, the X-axis moves left to right and is most useful for basic linear cuts.Our vertical, horizontal, and 5-axis machining centers combine stability, power, and accuracy with our proven technologies. Okuma’s machining centers are thoughtfully designed to manufacture high-precision parts and deliver impressive metal removal rates.This CNC machine guide will relieve the complexity surrounding 5-axis machines, how they work and why you might need one in your shop.High accuracy maintained with 5-axis machining Stable high-accuracy 5-axis machining is achieved even in a typical factory environment, with the synergistic effects of the Thermo-Friendly Concept and the 5-Axis Auto Tuning System.

Our new, next-generation, 5-axis vertical machining center is specifically designed to manufacture high-precision parts and deliver impressive metal removal rates in a compact design. Its solid double-column structure, full 5-axis simultaneous control, and thermal stability performance give it the ability to easily cut a variety of materials.The MU-4000V provides the power of process-intensive machining and high-speed, high-accuracy cutting through the combination of turning and 5-axis multitasking machining. The fast yet powerful trunnion table allows simultaneous 5-axis machining and one-chuck multi-sided machining of complex shapes.

The tool reaches the end of the workpiece even with the table at various inclination angles, enabling wide-range 5-axis machining. Tools can be changed with the trunnion still in a swing position, leading to reduced cycle times and higher machining accuracies.Improve productivity in process-intensive machining with this 5-axis vertical machining center. The GENOS M560V-5AX delivers stable machining accuracy and energy efficiency while providing a large work envelope in a small footprint.

Okuma has horizontal and vertical machining centers, including 5-axis machines, in a variety of sizes and configurations to meet any manufacturing needs.Our MU-6300V 5-axis vertical machining center achieves high efficiency and high productivity in 5-axis, multi-sided machining. This CNC vertical machining center's highly rigid and accurate double column structure and low center of gravity in workpiece movement (trunnion table) enable both heavy-duty cutting and high-speed finishing.The five axes of a 5-axis CNC machine are X, Y, Z (linear) and A and B (rotational). Understanding the unique function of each allows machinists to unlock the full potential and capabilities of the machine. In many machines, the X-axis moves left to right and is most useful for basic linear cuts.

Our vertical, horizontal, and 5-axis machining centers combine stability, power, and accuracy with our proven technologies. Okuma’s machining centers are thoughtfully designed to manufacture high-precision parts and deliver impressive metal removal rates.

benefits of 5 axis machining

This CNC machine guide will relieve the complexity surrounding 5-axis machines, how they work and why you might need one in your shop.High accuracy maintained with 5-axis machining Stable high-accuracy 5-axis machining is achieved even in a typical factory environment, with the synergistic effects of the Thermo-Friendly Concept and the 5-Axis Auto Tuning System.Our new, next-generation, 5-axis vertical machining center is specifically designed to manufacture high-precision parts and deliver impressive metal removal rates in a compact design. Its solid double-column structure, full 5-axis simultaneous control, and thermal stability performance give it the ability to easily cut a variety of materials.The MU-4000V provides the power of process-intensive machining and high-speed, high-accuracy cutting through the combination of turning and 5-axis multitasking machining. The fast yet powerful trunnion table allows simultaneous 5-axis machining and one-chuck multi-sided machining of complex shapes.

The tool reaches the end of the workpiece even with the table at various inclination angles, enabling wide-range 5-axis machining. Tools can be changed with the trunnion still in a swing position, leading to reduced cycle times and higher machining accuracies.

5 axis trunnion machining

Hole Size = D - (0.6495 x P x %). In this equation, D is equal to the nominal screw diameter. * Pilot holes listed under the 90% and 85% thread engagement columns are recommended for single punch extruded holes. Typical tolerance for the pilot home range is -10% to +5% from the nominal percent thread engagement.

5 axis cnc machining centre|small 5 axis cnc mill